An industrial PC is only as good as the consulting behind it

"In order to get an optimal industrial PC, you only have to select the appropriate components". What sounds simple at first can be quite complicated in detail: After all, what are the right individual parts? Who supplies industrial components? And do they fit together perfectly?

Many questions, and always one answer: Spectra.

Because at Spectra you are always looked after by experts.

At Spectra, advice, price and performance are right

Those who have demanding applications need selected good solutions. This can only be achieved through good advice and a high level of professional competence. How quickly can a system be delivered? What about special requests? What is the price/performance ratio? What happens in case of an error?

Experience

Spectra knows the answers to these questions. We have been successful in the field of industrial computer applications for over 30 years. In thousands of industrial applications we have proven our efficiency and our high quality standard. Year after year, we have gained experience from which you can particularly benefit.

Spectra advantages at a glance

- High level of consulting competence

- Competence in development and production

- Highest quality standard

- High-quality components

- Long-standing relationships with international suppliers

- Attractive conditions

Designed to requirement - from 1 to 1.000 pieces

90 % of all applications can be solved with standard components.

But what about the remaining 10 %? When individual adaptation is required? Who has the know-how and the means to fulfil such wishes?

The answer: Spectra.

Whether it is the design of a front in your corporate design, the construction of a particularly efficient cooling system or the design of a tailor-made computer board: We deliver the 100 % solution. And it is precisely this all-embracing service that sets us apart from many others.

In 6 steps to the optimal industrial PC

Every application is different. Every environment is different. But the requirement is always the same: reliability. Every industrial PC must therefore be designed a little differently: so that it is perfectly configured for the application.

Our experts therefore ask you first and foremost about the exact application, the ambient conditions and the technical requirements. To work out a solution based on this that is specifically tailored to your application.

1 | Needs Analysis

In order to specify your optimum system, our experts first clarify all relevant questions with you regarding the ambient conditions, the application, the special boundary conditions with regard to interfaces, the mass flow rate, the graphics and processor performance.

2 | System proposal

Based on the needs analysis, we work out a proposal for you for a customized tailor-made system. These system proposals can consist entirely of standard components or, if required, can include components specially manufactured for you.

3 | System decision

The decision then matures in dialogue with you. If necessary, you inform us of any changes you wish to make to the solution we proposed. We modify the configuration accordingly in order to create a cut IPC system that is exactly tailored to your needs.

4 | Scheduling

After receipt of your order, the production process starts with a careful production planning. A production order is created in the order system, a serial number is ejected by the planning software, the availability of the components for the system is checked, delivery times are clarified and the production of special components is initiated.

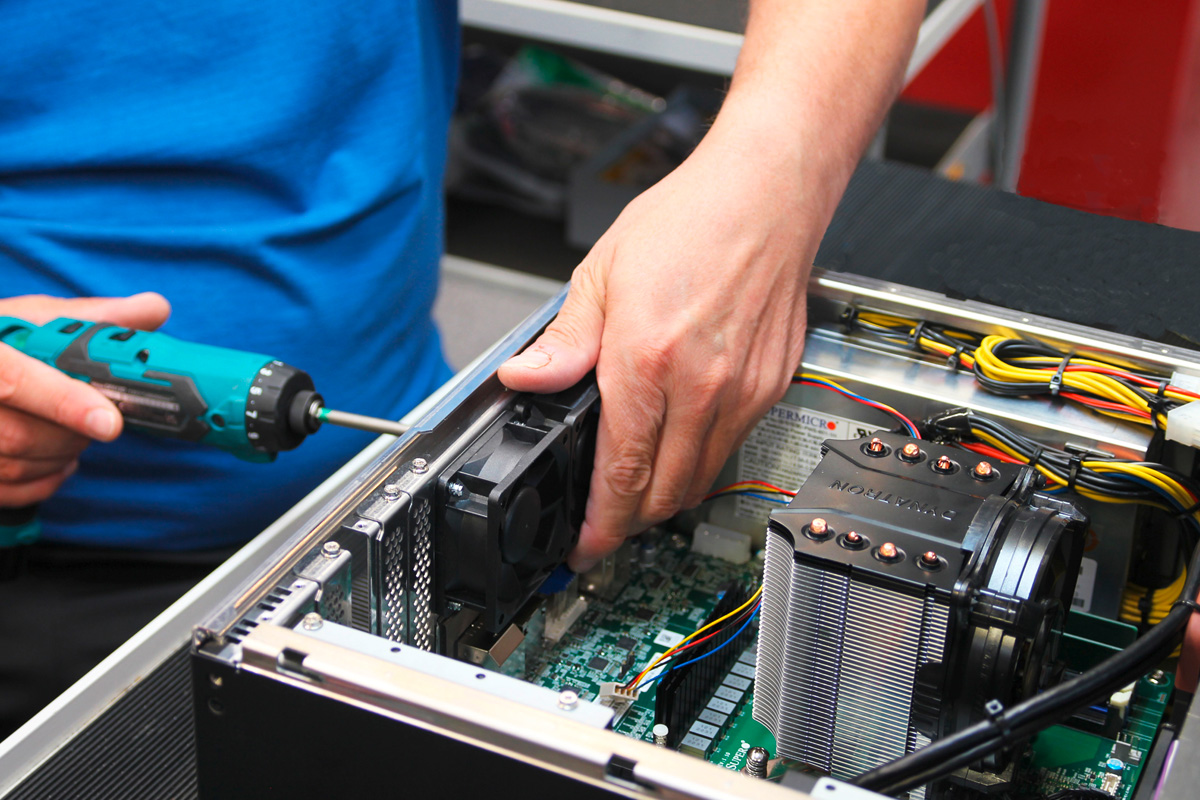

5 | Assembly

The system components are picked in the logistics centre according to the production plan. Production is carried out by qualified personnel and according to strict quality specifications. All installed components are provided with a serial number and are listed in the production order with the serial number of the complete system.

6 | Quality control

After completion of the assembly, the system is subjected to a 100% functional test. The IPC is operated for at least 24 hours under a very high system load in order to detect faulty components with a high probability. After completion of the test, a quality certificate is issued, which is enclosed with the finished system.